Track-Pac

Home » Track-Pac

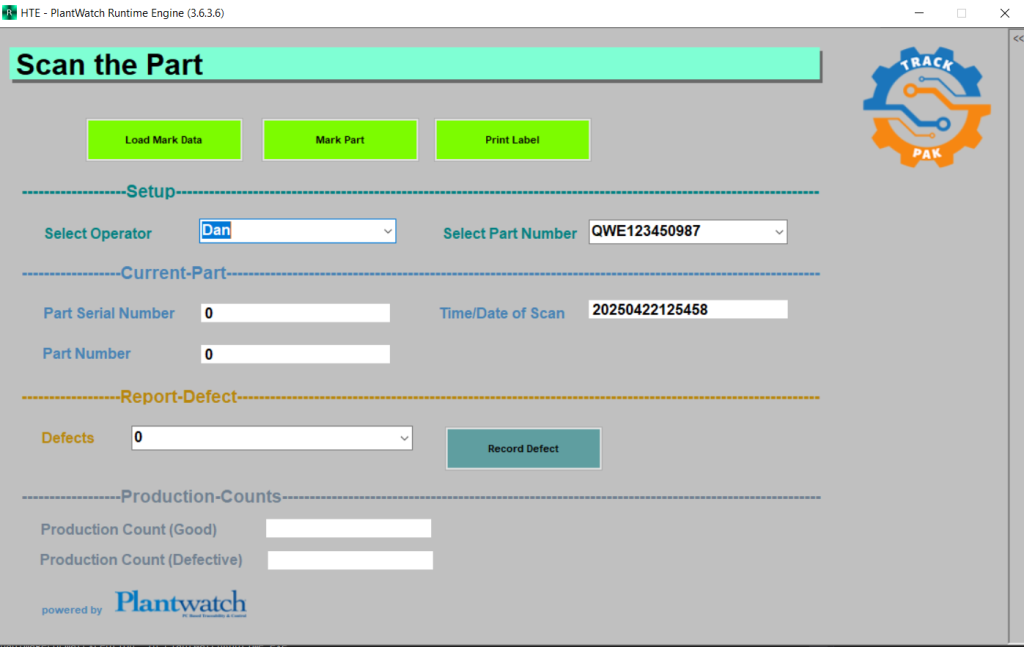

Complete traceability package

- Track-Pac combines a powerful “Do it yourself” software package with hardware to perform customizable plant floor functions.

- Configured to perform data collection, Quality control, traceability, and other MES functions.

- One-time purchase of the transferable permanent license.